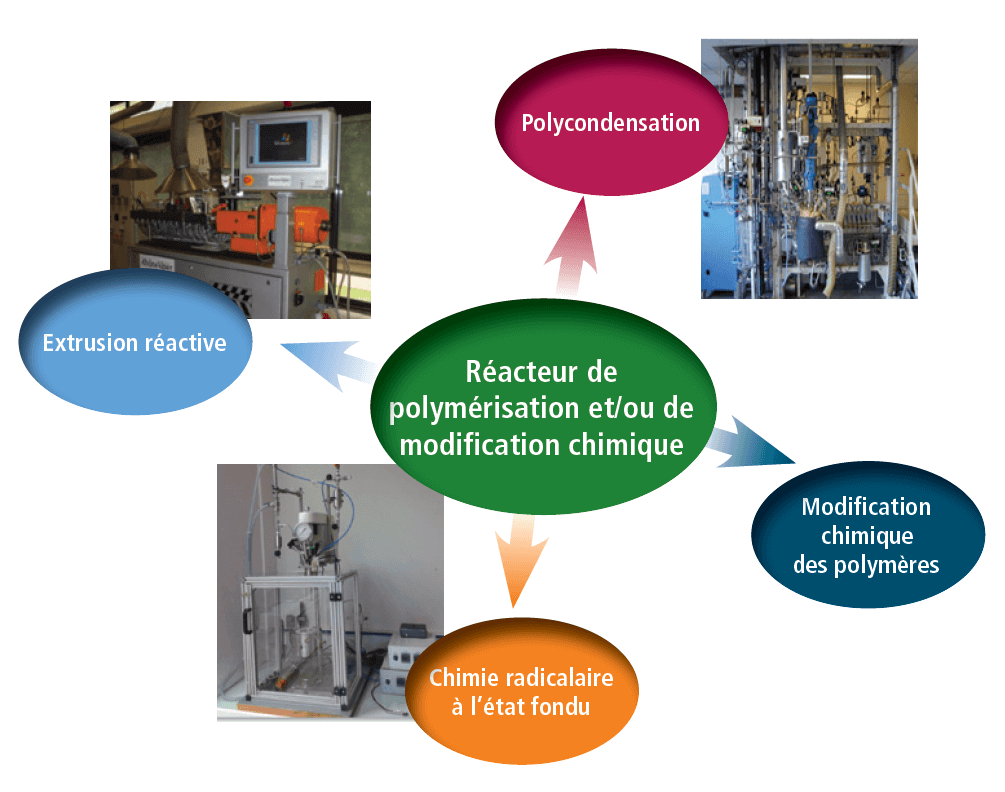

REACTeurs pilotes de polycondensation : Chemical synthesis and modification

REACTeurs pilotes de polycondensation : Chemical synthesis and modification

Polycondensation reactor: Polyester (Missenart Quint)

Vol = 7.5L, Tmax = 300°C, Pmax = 7bar, fully automated

Ancillary equipment: granulator, solution viscosity measurement station, acid-base dosage station

Polymerisation of aromatic (co)polyesters (PET, PTT, etc.) and aliphatic (PBS, etc.)

Polycondensation reactor: Polyamide (Premex/ISL)

Vol.=1L, Tmax=350°C, Pmax=50 bars, window, fully automated

Ancillary equipment: granulator, solution viscosity measurement station, acid-base dosage station

Polymerisation of aromatic (PA6/T,PA6/I,PA6/F, etc.) and aliphatic (PA6/6, PA11, etc.) (co)polyamides.

500 mL stainless steel reactor (Parr)

Vmax = 500 mL, Max pressure = 200 bars; T max = 350°C

Ancillary equipment: reagent addition bulbs; gas sampling systems

Grafting of methyl methacrylate on pentadecane

Optimax glass reactor (Mettler-Toledo)

V = 1,000 mL, Pressure = 0.05 at 1 bar; T = – 40°C at +180°C; V agitation = 30 at 1,200 rpm

Oxidation and functionalisation of graphitic loads

3 twin-screw extruders for reactive extrusion

Leistritz; Dvis: 18mm, L/D: 60, N:1,200 trs/min.

Clextral; Dvis: 27mm, L/D: 48, N:1,200 trs/min.

Clextral; Dvis: 21mm, L/D: 40, N: 600 trs/min.

Ancillary equipment: sensors (UV/Fluorescent, IR, pressure, etc.), weighing and liquid dosers, side booster, devolatisation, etc.

Applications: Mass polymerisation, radical grafting, functionalization, reactive compatibility, load modification and in-situ generation

Contacts

Site INSA Lyon

Alain ROUSSEAU

Françoise FENOUILLOT

Régis MERCIER

Site Université Lyon 1

Emmanuel BEYOU