COATingXpert

COATingXpert

Coating application

This technical centre is a pilot centre for the application of paints, process studies and training.

Automated semi-industrial chain

Application of liquid paint: Dual-track conveyor, adjustable up and down, with 3 sprayers equipped with nozzles or bell cups. Applications are pneumatic or pneumoelectrostatic. Solvent-based, hydro- or photocure paints can be applied automatically or manually.

Application of liquid paint: Dual-track conveyor, adjustable up and down, with 3 sprayers equipped with nozzles or bell cups. Applications are pneumatic or pneumoelectrostatic. Solvent-based, hydro- or photocure paints can be applied automatically or manually.- Application of powder paint: A powder booth for manual application.

- Drying or polymerisation:

By convection oven, IR convectors and UV lamps (microwave or electrode type). On a laboratory bench with a conveyor, mid and near IR, UV is also available for all types of studies. - Surface treatment can be carried out using an atmospheric plasma torch with a rotating nozzle.

The platform, supported by the laboratory of the plastics processing site, is equipped with:

The platform, supported by the laboratory of the plastics processing site, is equipped with:

– Industrial control means: adhesion comb, glossmeters, microwave scan, pull-out test per plot, thickness measurement

– Research and characterisation instruments: viscosimeter, microtome, binocular magnifier and SEM, Digidrop, traction machines, ovens, etc.

Examples of studies include

- Application of low-temperature powder paint on a composite

- Application of 100% dry extract UV varnish

- Search for surface treatments on polymers

- Application of touch-up paint on a high-temperature surface

Equipments

- Powder cabin for manual application

- Convection oven, IR convectors and UV lamps (microwave or electrode type)

- Laboratory bench with conveyor, mid and near IR, UV

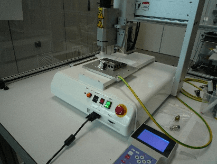

- Atmospheric plasma torch with a rotating nozzle

Contact

Summary