PROCESS : Implementation and formatting processes

PROCESS : Implementation and formatting processes

This technical centre, spread over the three sites of the IMP, offers different technologies for implementing and shaping molten polymers.

Equipment for preparation and shaping

- Reactive extrusion and compounding at different scales

- Shaping of characterisation specimens

Examples of studies include

Reactive extrusion

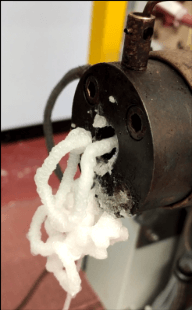

Extrusion of supercritical CO2 foaming

Scale up: twin-screw extrusion

Mini-extruder

Equipments

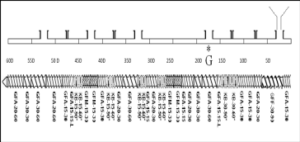

- Twin-screw and single-screw extruders (Tmax= 400°C)

- Internal mixers (Tmax= 500°C and V= 50 cm3 to 300 cm3)

- Vertical twin-screw micro-compounder (Tmax= 450°C and V=15 cm3 )

- Horizontal mini-extruder (Tmax= 350°C and V=7 cm3 )

- Extrusion-blowing

- Extrusion cast

- Roller/calender mixers (Tmax= 250°C)

- Chitosan spinning driver

- Injection presses (6T to 50T)

- Compression presses (Tmax = 400°C)

- Thermoforming machine

- Grinders

Contacts

Summary