FABrication additive

FABrication additive

This technical centre brings together the main additive manufacturing technologies and offers a set of versatile means for working on small quantities of material for research, development, screening, etc.

Available processes

- Melted wire deposit (Fused Deposition Modelling, FDM, or Fused Filament Fabrication, FFF):

Open machines

– Used in prototyping, creation of small adaptation parts for multiple projects,

– tests on the ability to process different polymers and on the adhesion between two polymers during manufacture

- Stereolithography Apparatus (SLA)

- Selective Laser Sintering (SLS)

Use of a wide range of professional thermoplastic powders (PA 12, PA 11, TPU) and charged powders (glass, aluminium, carbon, etc.)

Examples of implementation

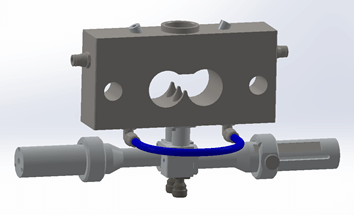

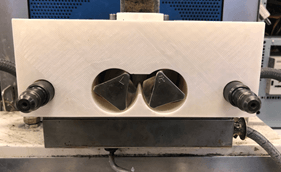

Internal mixer chamber for simulation of microwave heating (ANR MOMix)

Équipments

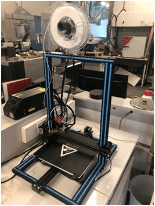

FDM CREALITY CR10®

- Manufacturing volume and resolution: 300X300x400 mm (between 100 and 400 µm)

- Open machine

FDM TOBECA ®

- Manufacturing volume: 300X300x300 mm

- 2 modules available:

- 2 nozzles powered by filament coils for printing with two materials

- A small hopper feeding the nozzle with granules for testing specifically formulated materials

- Open machine

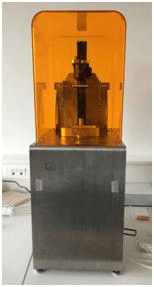

SLA Formlabs ® Form 2

- 405 nm laser

- Manufacturing volume and resolution: 145 x 145 x 175 mm (XY: 140 µm)

MicroSLA® TITAN 3

- 365 nm DLP, UV LED source

- Manufacturing volume and resolution: 48X27x250 mm (25 µm) and 192x108x250 mm (100 µm)

- Lamp power: 700 mW

Sharebot® Snowwhite

- CO2 laser (14 W)

- Manufacturing volume and resolution: 100X100x100 mm (XY: 100 µm, Z: 50 µm)

- PA 12, PA 11, TPU and loaded powders (glass, aluminium, carbon, etc.)

- 2 machines available, one of which can be stored under inert conditions in a nitrogen atmosphere

Contacts

Summary