RHÉOLogie

RHÉOLogie

This technical centre, spread over the three sites of the IMP, is tasked with characterising polymer materials from the melted state to the solid state and low viscosity liquids to study the stress-strain relationships in the melted or solid state.

Characterisation of polymers

Characterisation of polymersStructure/properties relationship in molten polymers (viscoelastic magnitudes – molecular structure, crystallisation – polymerisation reaction/freezing time, transitions – load dispersion, network formation)

Characterisation of polymersStructure/properties relationship in molten polymers (viscoelastic magnitudes – molecular structure, crystallisation – polymerisation reaction/freezing time, transitions – load dispersion, network formation)- Rheological behaviour for shaping (flow at high shearing rates – swelling)

- Mechanical properties (torsion module, bending, compression and time/temperature tension)

- Rheo-dielectric properties (percolation threshold, permittivity, conductivity)

Examples of studies include

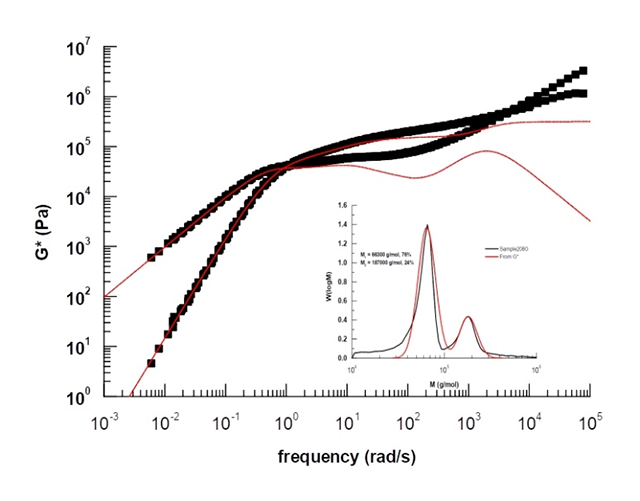

Rheological interconversion – molar masses

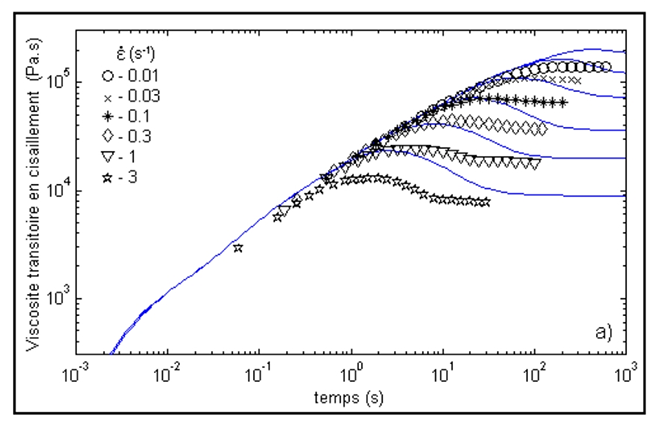

Polyethylene elongational rheometry at 160°C

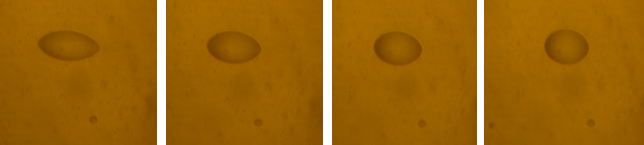

Measurement of interfacial tension by the relaxation of drops (PEG in ethylene octene copolymer)

Equipment

- Dynamic Mechanical Analysis, DMA (Q800-Q850- DMA 1 – DMA861)

- Controlled stress rheometers (HR20-DHR2-AR2000-MCR301-MCR702)

- Controlled deformation rheometers (ARES G2-ARES)

- Elongational rheometers (EMR, SER, EFV)

- Forced-flow capillary rheometers (RH 2000- RH7-Instron)

Contacts

Summary