Stage M2 : NEW SUPERPLASTICIZERS SYNTHESIS BY POLYCONDENSATION

pdf file to downloadContext

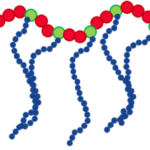

Superplasticizers are advanced chemical admixtures specifically formulated to significantly improve the fluidity and workability of cement pastes without increasing the water content (Figure 1). These additives play a crucial role in modern concrete technology by enabling high-performance mixes with superior strength and durability. Among the various types of superplasticizers, polycarboxylate ethers (PCEs) stand out as the most widely used due to their exceptional dispersing capability. PCEs are comb-shaped copolymers characterized by a backbone containing carboxylic acid groups and side chains composed of poly(ethylene glycol), which provide steric hindrance and enhance particle dispersion.[1] Typically, these polymers are synthesized through radical polymerization processes, allowing the control of their grafts and charge density. The structural design of superplasticizers—particularly the length and density of side chains and the distribution of carboxylic acid groups—is the key factor in achieving targeted performance characteristics such as slump retention, water reduction, and compatibility with supplementary cementitious materials.

Figure 1. Schematic representation of an actual superplasticizer

The cement industry is rapidly evolving to meet sustainability targets, driving the development of binders with lower clinker content and reduced active phases[2]. While these changes significantly cut CO₂ emissions, they introduce a new challenge: maintaining fluidity and workability in systems with fundamentally different chemistry. Conventional superplasticizers often fail to deliver optimal performance under these conditions, opening an exciting research frontier.

In the frame of this internship jointly conducted by the IMP laboratory (Lyon) and Saint-Gobain, we want to develop superplasticizers through step-growth polymerization instead of chain-growth polymerization with the aim of:

- Designing unprecedented polymeric structures with controlled functional content and structures via the careful selection of monomers,

- Investigating the structure–property relationships in collaboration with the teams of Saint Gobain Solutions for Concrete and Cements to understand how molecular design impacts the main properties of the superplasticizers in concrete compositions (adsorption, dispersion, and rheology.)

[1]Ma, R.; Wang, Y.; Li, H.; Bai, Y. Progress in the Polycarboxylate Superplasticizer and Their Structure-Activity Relationship – A Review. Materials Today Communications 2023, 35, 105838. https://doi.org/10.1016/j.mtcomm.2023.105838.

[2]Tayebi, M., Kamala Ilango, N., Nguyen, H., Lori, A. R., Ranjbar, N., Carvelli, V., & Kinnunen, P. (2025). New insights into hydration of MgO in the presence of polycarboxylate ether superplasticizers. Cement and Concrete Composites, 162, Article 106153. https://doi.org/10.1016/j.cemconcomp.2025.106153

Skills acquired during the internship:

– Polymer synthesis via polycondensation reactions with different processes (bulk, solution etc)

– Characterization of polymers (FT-IR, 1H and 13C NMR, SEC, DSC, TGA, solubility)

– Study of structure-properties relationships

– Preparation and presentation of supports for discussion with partners from Saint-Gobain.

Info & contactpersons:

Location of the internship: The internship will take place at the IMP laboratory located at INSA-Lyon component on the “La Doua” campus at Villeurbanne (69).

Duration and remuneration: 5 or 6 months, starting in February 2026. Remuneration in agreement with current French legislation

Application: please send a CV and a motivation letter to

After a first selection based on resume, an interview will be organized with the academic supervisors. Always interested in potential PhD candidates, an interview with St-Gobain’s collaborator Dr Vincent Froidevaux will also be planned.